Discrete event systems and applications

Responsible: Prof. Francesco Basile

Supervisory Control of Discrete Event Systems

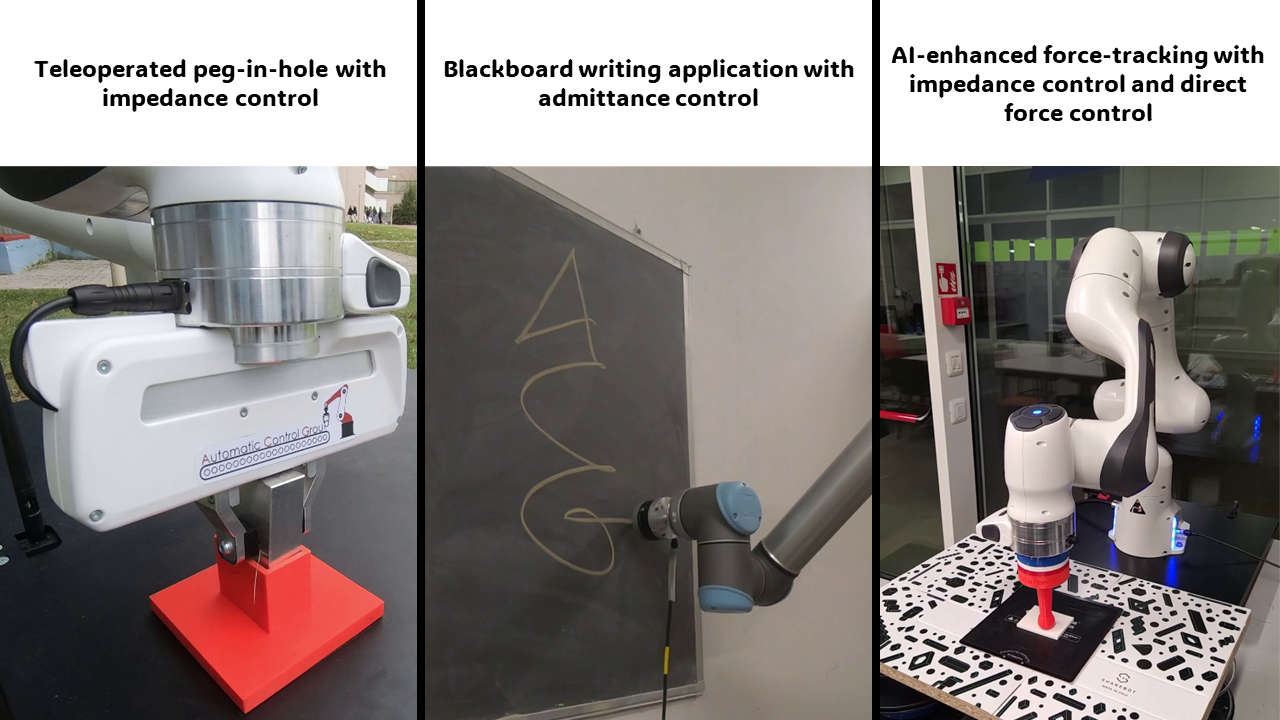

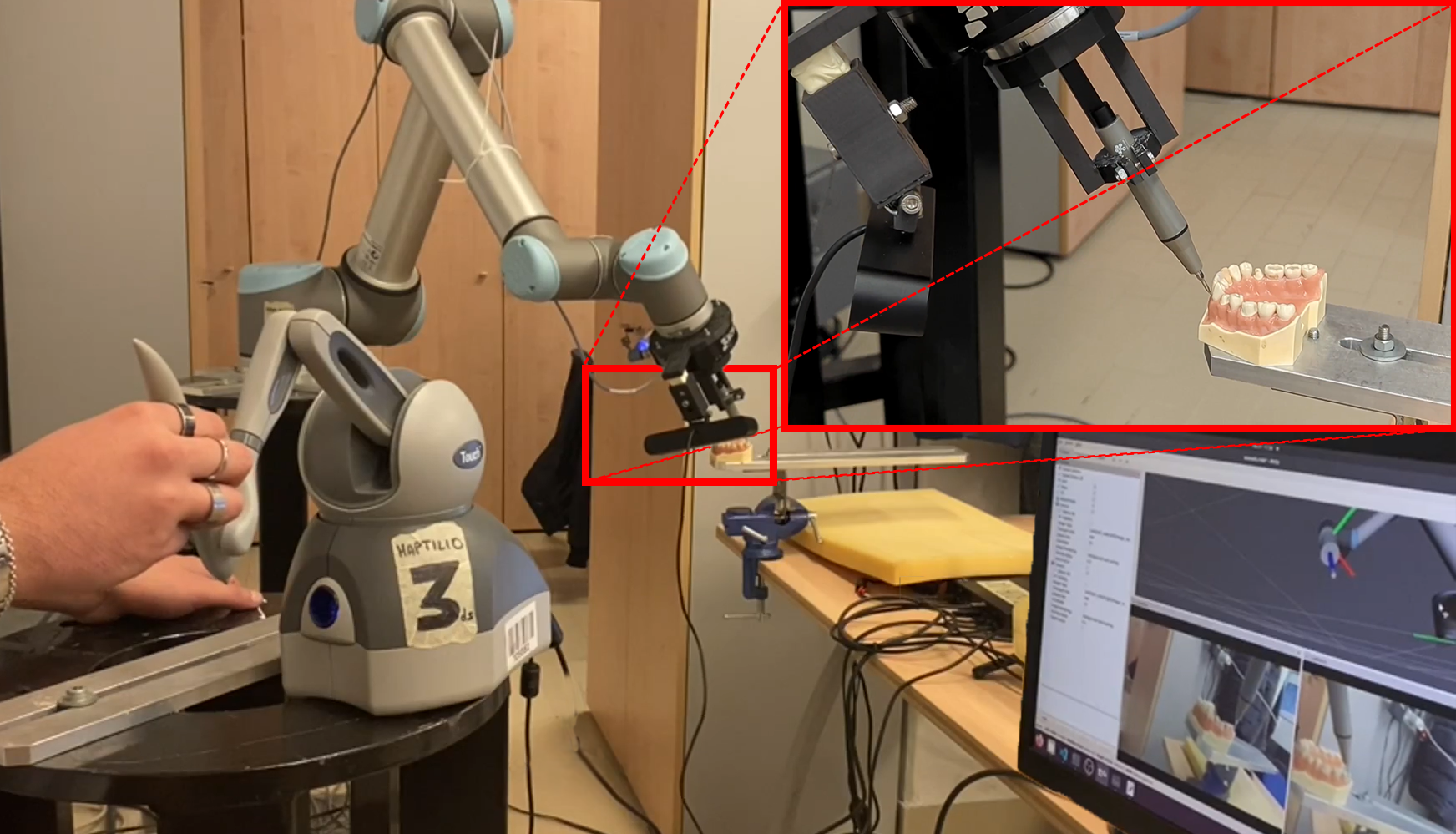

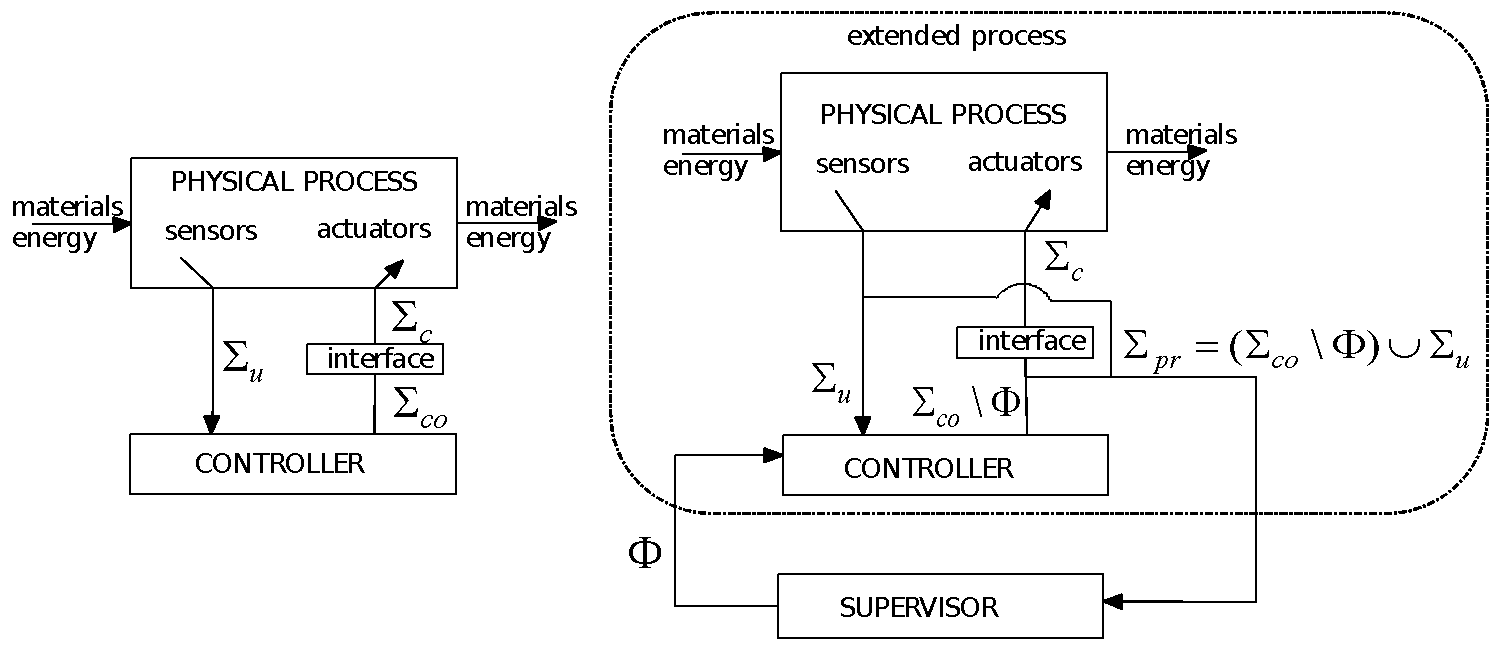

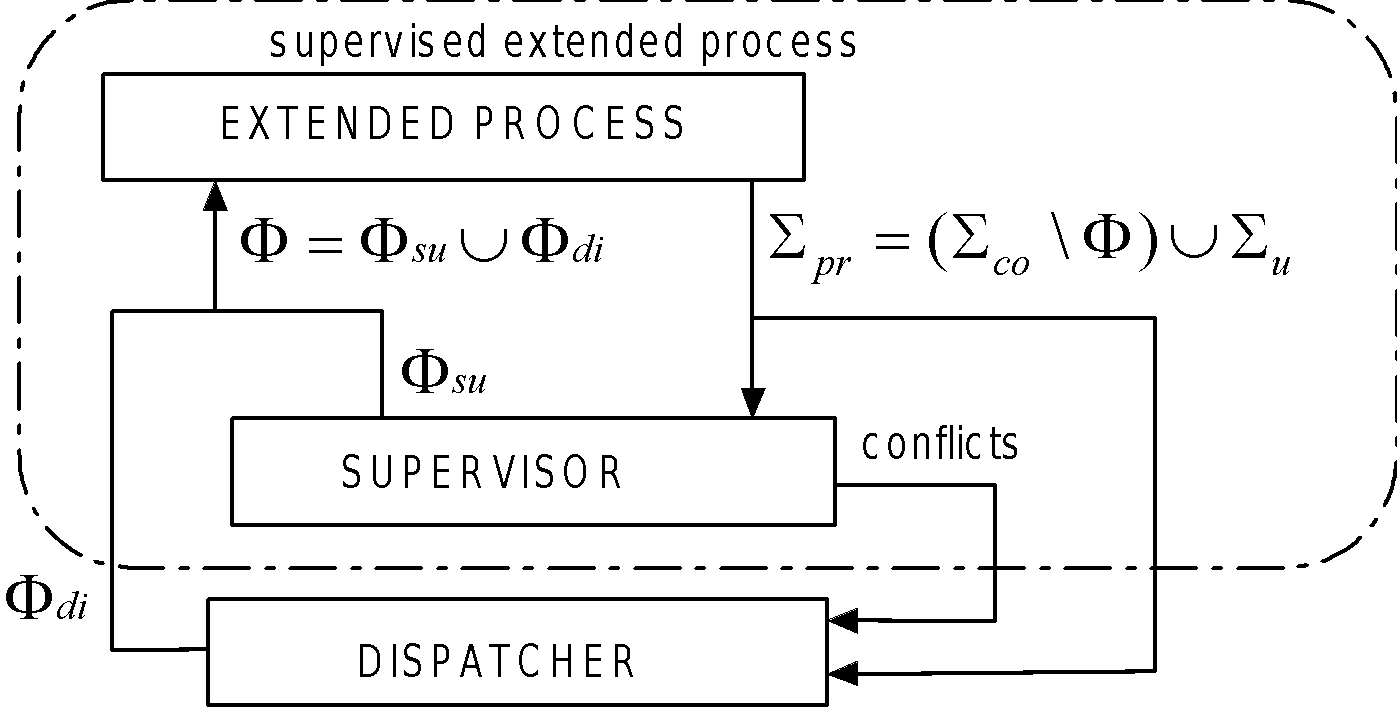

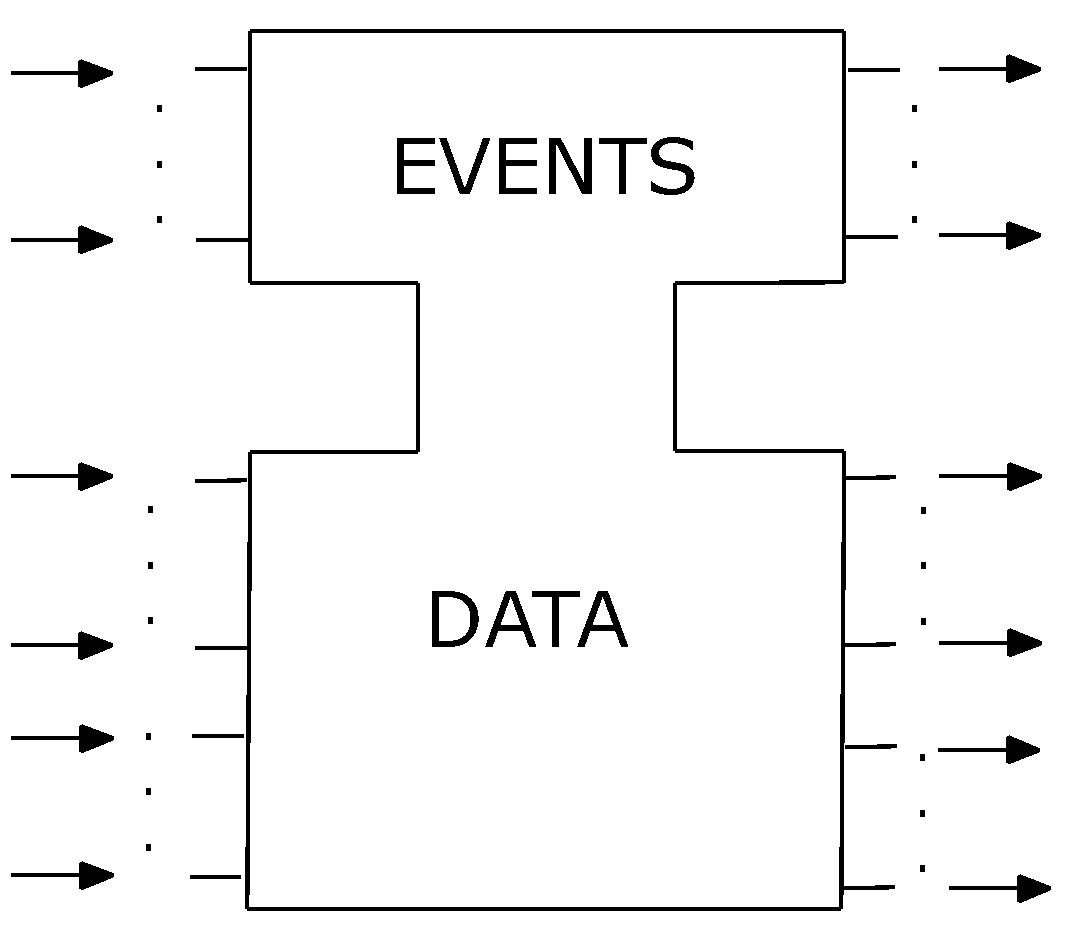

A physical process can be modelled as a DES when it is of interest its behavior in terms of forced and generated events. The control problem is, known the occurred events, forcing events in such a manner that a desired behavior is obtained. In DES control theory it is assumed that a symbol is associated to each event and the behavior of a DES can be described in terms of generated sequences of events/symbols that form a language. A more efficient approach is to split the control problem in two parts: the command of subsystems and their coordination. This is known in the literature as the supervised control approach. The physical system plus the forcing controller is regarded as an extended process for which events are considered as spontaneously generated. Supervisory control theory provides powerful results for Discrete Event Systems (DESs) where events are spontaneously generated (event occurrence cannot be forced) and, some events, named controllable events, can be disabled, while the other ones are called uncontrollable events. As for uncontrollable events, their occurrence can be just observed. An external agent, called supervisor, disables the occurrence of controllable events in order to enforce logical constraints on the sequence of events generated by the system. The advantage of this approach is that the supervisor must only manage coordination of (controlled) subsystems without considering direct control of the subsystems (delegated to the forcing controller). Noticeably, if coordination specification are changed only supervisor must be re-designed, while the subsystems’ controller is not affected. At the same time the abstraction of supervisory control theory that assumes events spontaneously generated by the physical process, useful for simplifying theory, is preserved and the implementation is not ambiguous (control and supervision concepts are not mixed). The main research activity of our group focuses essentially on the supervisory control based on Petri nets with logical and timed specifications.

Implementation of Discrete event control systems

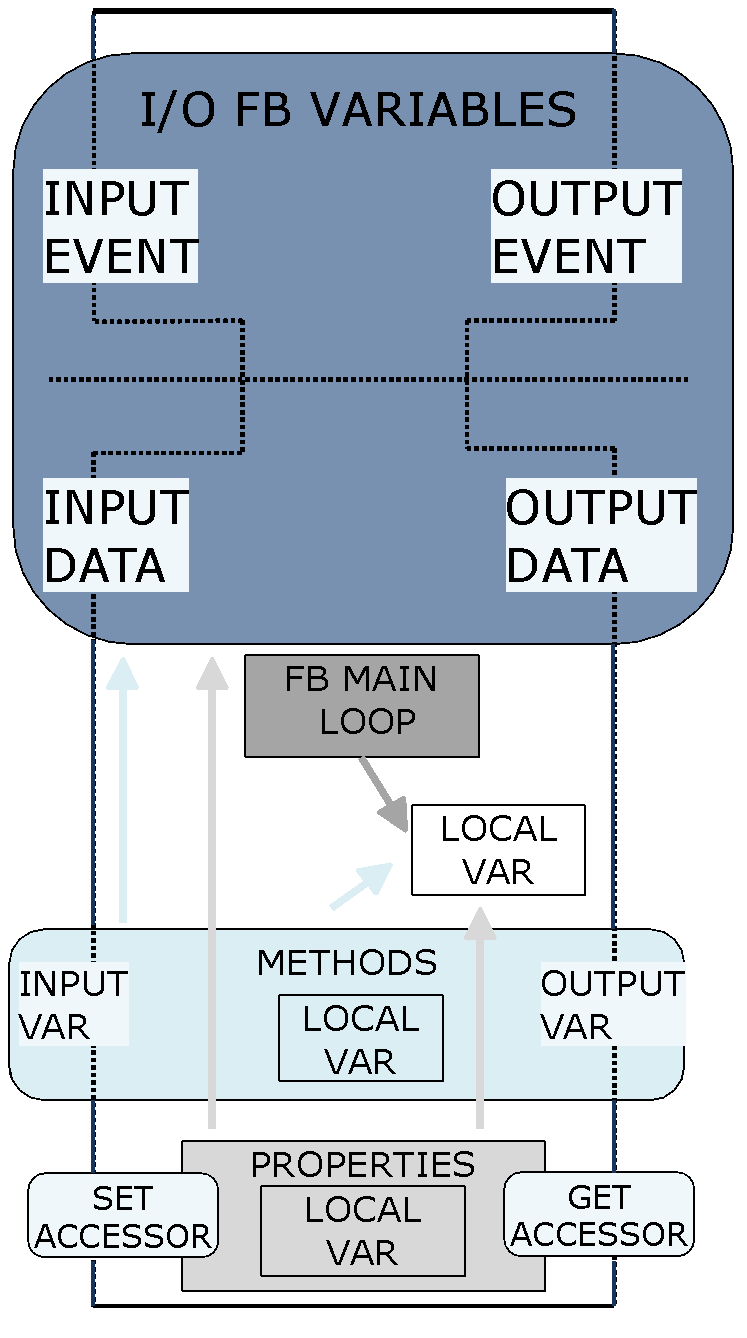

Supervisory control theory is nowadays well developed, but its use in industrial applications can be limited by a set of problems arising from implementation of supervisors on common control machines. As a matter of fact, the asynchronous nature of supervisors and the fact that they are non-deterministic models make their implementation on synchronous devices like Programmable Logic Controllers and personal computers not a simple task. The supervised control architecture consisting of a controller and a supervisor must be completed by a dispatcher to obtain a closed loop deterministic behavior. The main research activity of our group focuses essentially on the design and implementation of supervisors on industrial control machines starting from a formal definition of the controlled system’s behaviour and from the control specification but at same time as much as possible compliant with IEC standards for the implementation of control systems (IEC 61131 and 61499).

Fault diagnosis of Discrete event systems

In DES faults are usually represented as unobservable events, because their diagnosis would be trivial if they were observable. Fault events are not the only unobservable ones. In words, fault detection consists of on-line monitoring the system using the record of observed events to timely provide the set of faults that could have happened. A problem strongly related to fault diagnosis is that of diagnosability, that is equivalent to determine if, once a fault has occurred in the system, its occurrence can be detected in a finite number of steps. Diagnosability of DES deals with the possibility of detecting, within a finite delay, the occurrences of fault events using the record of observed events. The main research activity of our group focuses actually on fault diagnosis of timed DES.

Identification of Discrete Event Systems

The interest for the identification of DESs usually comes from reverse engineering for (partially) unknown systems, fault diagnosis, or system verification. The data collected from the observation of a discrete-event system are usually given in terms of behavioural sequences that may be fixed or may be increased in the course of the system operation (e.g., due to new experiments or simply to the system running). An identification algorithm of DESs produce a mathematical model expressed as a Petri net (PN) or a finite state automaton model of the system behavior from sequences observed during the system. The main research activity of our group focuses actually on the identification of timed DES.

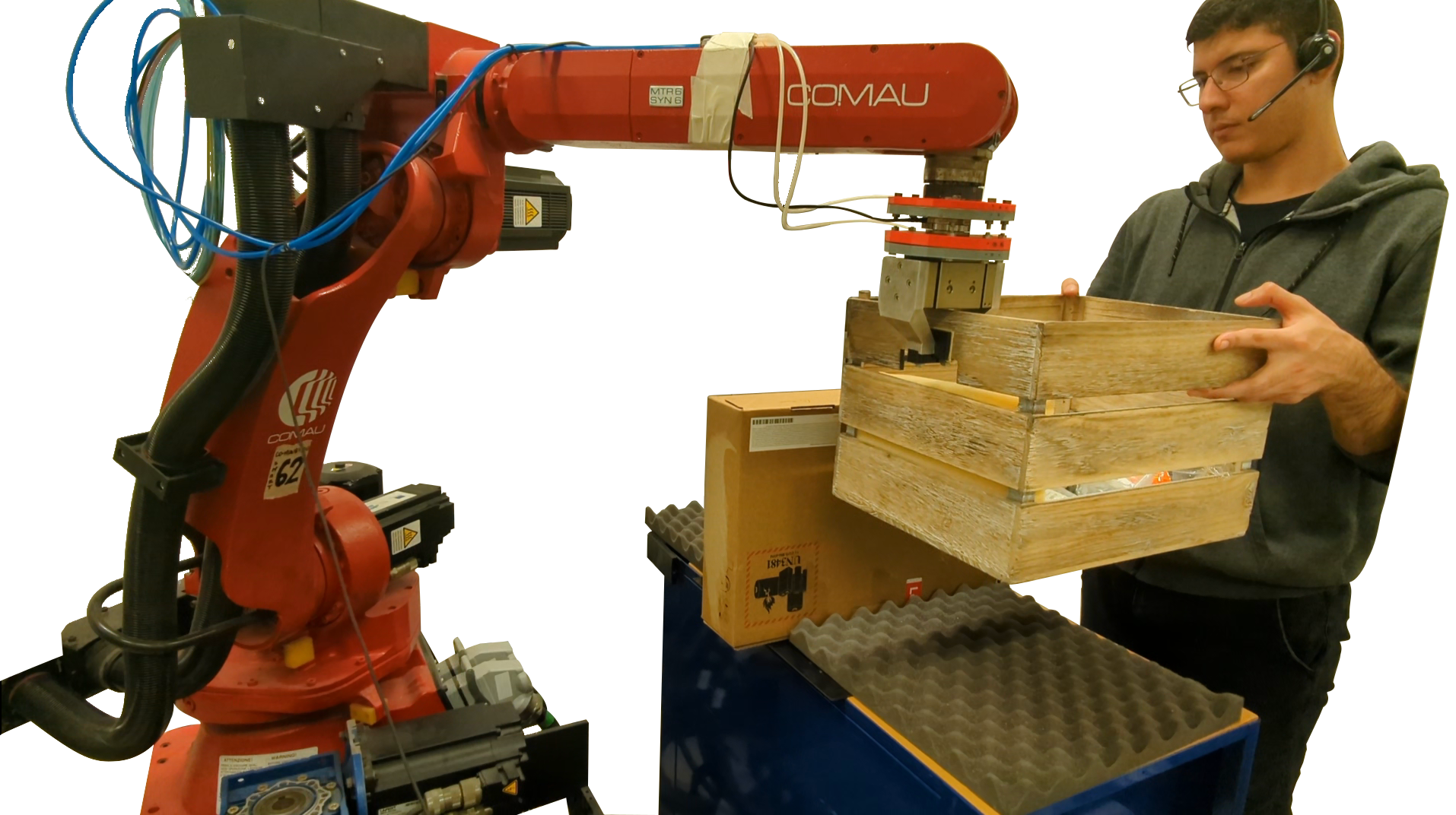

Simulation Based Control

Optimization methods attempt to determine the values for the controllable variables of a system so that a certain outcome of the system is optimized. Many of these systems can be formulated analytically and optimized by various techniques of mathematical programming. However, there are more complicated systems, often stochastic in nature, for which the objective function cannot be expressed analytically. For many of these problems, the analyst must resort to computer simulation to evaluate the system. If a decision policy is defined as a set of values for several quantitative variables, it is easy to see that simulation can be efficiently used as a means of optimization of the corresponding system. In other words, simulation response can be used as an objective function of an optimization problem for which the decision variables represent the variables that have to be optimized. The main research activity of our group focuses essentially on simulation control approach for logistic and automated warehouse control systems.